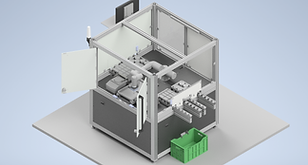

MODULAR ROBOTIC

WORK CELLS

Unmatched Application Flexibility.

Robotic work cells are enclosed units that contain one or more robots, and other mechanisms required to complete a specific process safely and efficiently. Up to 3 work cells can be interconnected.

-

Standalone or insert into existing process.

-

IPO principle (Input-Process-Output)

-

Interconnect up to 3 cells.

-

Easily movable (casters and leveling feet).

-

Windows based QC and Data Management.

APPLICATION STORY

One of the biggest benefits of integrating robotics into your manufacturing is a reduced labor cost. As many business owners know, finding labor can be difficult and time-consuming. A workcell can maintain or increase product output, without any additional hiring needed.

1

Reduced labor costs

Purchasing a pre-designed and pre-engineered workcell is significantly more cost-effective than a completely unique and customized robotic solution. At EIS Automation, we use modular technology that allows us to use our pre-engineered workcell to keep costs competitive, while offering customization to scale the work cells to the individualized sizes and capabilities needed to meet your industrial needs.

2

Reduced Purchasing Costs

An important benefit of integrating robotics into your manufacturing process is that they have an incredibly high degree of accuracy and repeatability that is impossible to achieve through human-only labor.

3

Maximized Efficiency

Any time a large, quick-moving unit is added to the manufacturing floor, the opportunity for accidents can increase. However, workcells are specifically designed to complete their process in an enclosed space which limits the opportunity for accidents. Additionally, our workcells are equipped with interlocks to automatically stop the equipment if an operator accidently opens the work cell during production.

4

Increased Safety

Workcells are designed to work quickly and efficiently. They can increase your product throughput via reduced downtime and increased production rate. Robots are able to complete tasks more efficiently than an employee due to human nature and error.

5

Increased Product Throughput

Learn about robotic work-cells.

As more and more businesses are stepping into industry 4.0, robotic work cells are becoming an easy-to-integrate and accessible way to improve industrial operations and overall productivity.